Bang goes the engine part 2

“I can hear it still needs a service.” — me being prophetic, August 27th, 2023.

Oh you didn’t think we were finished with part 1, did you? Well I did. On Monday morning it sure looked fine, but I started moving the boat and half a mile later badoom it went once more. But this time it was a seal at the other end of the coolant reservoir:

Still… the same issue, one big HMMM. An hour later after a trip to the chandlery and replacing it, I started the engine with a keen eye. So far so good, but I wasn’t convinced yet.

Sure enough, 10 minutes later and a little heat, wisps of smoke began floating from somewhere. I couldn’t tell from whence they came, but I checked the oil and the coolant reservoir again. The oil looked fine — black and shiny — but the coolant was bubbling… ruh roh. That mostly sealed the deal; it was probably the head gasket, which meant taking the engine apart. My first thought was to find an engineer, so I called James for a recommendation (remember the gentleman that helped with the welding?), but his vote of confidence spurred me to have a go myself: “Oh it’s totally DIY-able, you just twizzle the fluxtromater, remove the turbo encabulator and scrazzle the marzlevane.”*

“Of course, Nicholas, you are the engineer!” I could hear my angels sing.

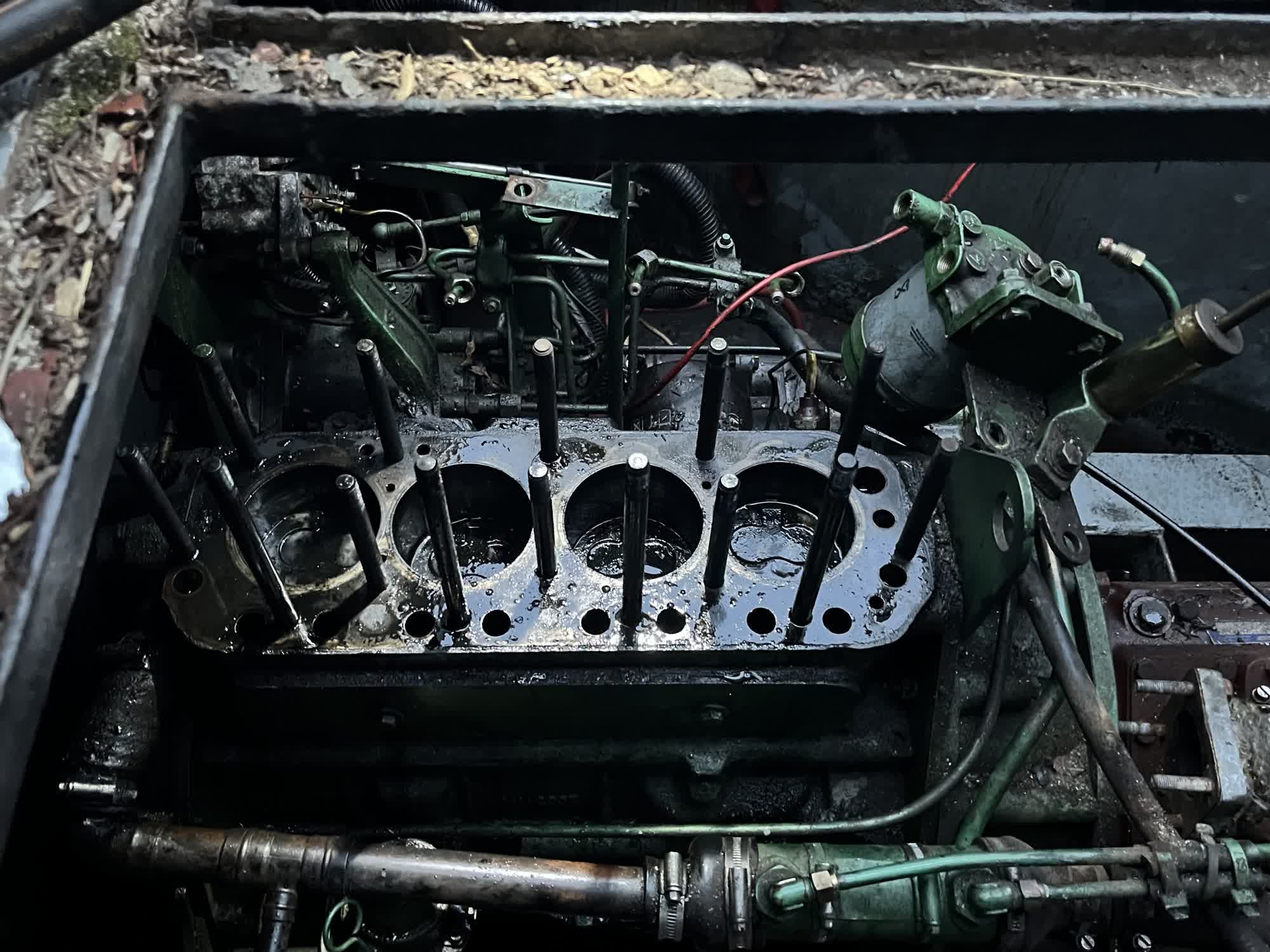

It started fine, but I needed a tooling upgrade, and with a new socket set from Screwfix we were back in business. Honestly? This was a bitch, but by jove was it fun and funny. 5 hours later and there it was, in all its greasy, gunged up glory:

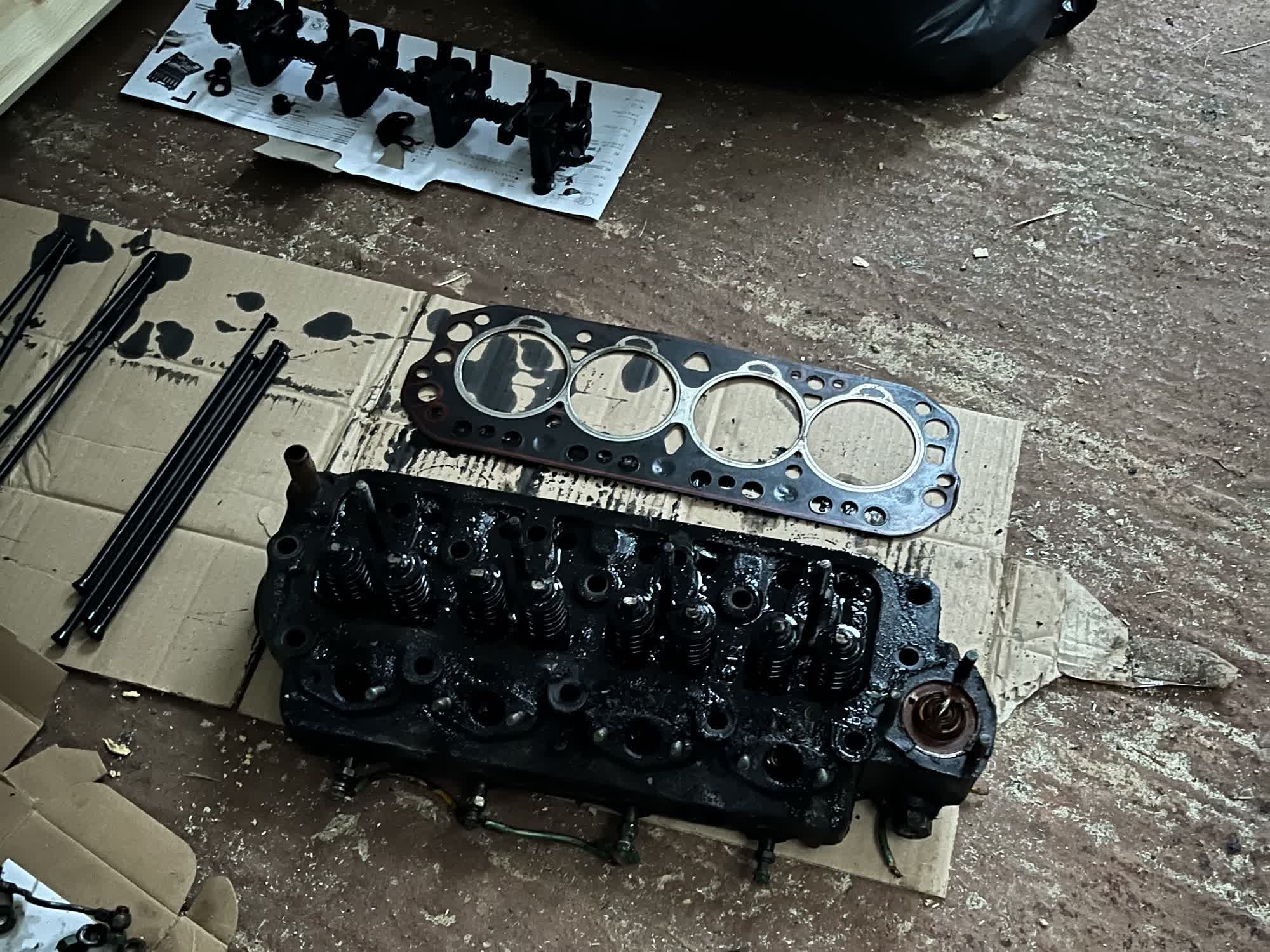

When I finally got the gasket off it wasn’t an obvious explosion, but there was some carbonation on the engine head between a cylinder and a water channel which could very well explain these mis-happenings; the tolerances are tiny, so it doesn’t take much.

This was all new territory for me, and even just dismantling it taught me a lot. I’m excited to put it back together, and it’s only Monday. On the plus side, the internet was slightly better than my previous spot, and also how lucky am I for this to happen in August?! Imagine how shitty this would be in December.

On Tuesday I spent a couple of hours trying to remove the engine water pump, but… there was this one nut, behind the pulley, playing hard to get. So much so, I didn’t even get it. I borrowed a pulley removal device thingy, but unfortunately that was too big to fit, and as of writing it’s still in place (other jobs to do!).

I took the engine injectors to Bob Beck’s in Leamington for a service, followed by the engine head to Ward’s in Rugby, a machine shop for refacing it. They did a leak test as well, which luckily went fine, otherwise it would’ve been a couple of weeks for them to do a full service, removing and cleaning the valves, etc. I wasn’t around to pick it up this week, but will do that tomorrow (Monday)!

And on Thursday, finally, my 10 tubes of sealant arrived! I couldn’t wait to install the windows and seal the rest… on Friday. Rain was on-and-off all day, so I went on a goose chase for a multipoint lock.

Although less of a chase, more of a mission to a locksmith near Bournville. I walked in and told the guy my dilemma: “I’m renovating a boat, and want to install a multipoint lock on the door… I don’t know what I’m looking for, can you help?”

He proceeded to laugh; one doesn’t simply install a multipoint lock on a door that isn’t designed for it. After serving some other customers and a long back-and-forth, he gave in to my vision…

Him: “It’s too long”

Me: “Can’t I just cut it? I could also weld a new bit on.”

“Err, no.”

“Why not?”

“Well… you need these things,” pointing at some teeth on the protruding bar.

“Why? I could make my own.”

He was incredibly good-humoured, and amused by my determination. The alternative would be a couple of latches — the norm for securing boat doors — but that’s far too many steps compared to simply lifting a handle.

Him: “You know, you’re gonna start on this and then regret doing it” he said with a smile.

Me: “I know, and it’s gonna be great.”

I now have all the pieces to build me the door lock of my dreams, and it’s going to be bloody fantastic. This boat will ironically go from open wind tunnel that welcomes all to one of the best-locked vessels in the kingdom. I might even install a cannon and take it to France.

Friday, with newly-replenished sealant, I installed 2 more of the kitchen windows, and the final one on Saturday morning:

Followed by sealing the other 3 windows on the port side:

And would you believe it, this side of the boat is now watertight! I also installed the final 2 vents on the roof, and shaped the bottom of the front window before giving it 2 coats of primer for the outside:

I’ll varnish the interior-facing wood next week, install the window pane and then fix it to the boat. It’ll then need some shaping to fit the hull’s contours, followed by some extra primer.

This is turning out to be a great week, even after the poor engine had a bad day, and I’m excited to clean it all up next week.

Until next Sunday!

- Nick

P.S. You can now subscribe to receive new posts via email! There’s a form just below.

*Not actually James’ words.